Acoustic Emission

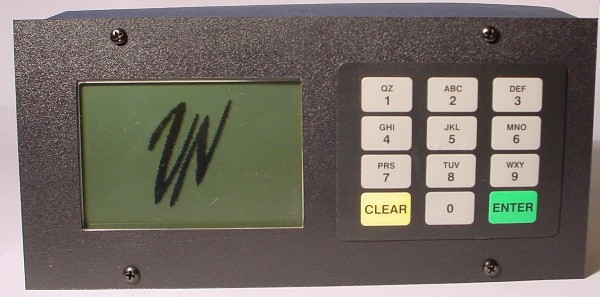

VN500 Welding Control System Contacto

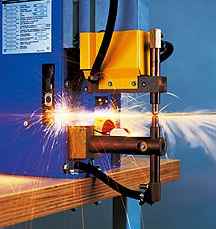

Detects and analyze spot and stud welding quality on the fly.

-Detects ultrasonic signatures in metal or piece and not current or voltages in welding machines.

-Analyze welding heating and cooling patterns.

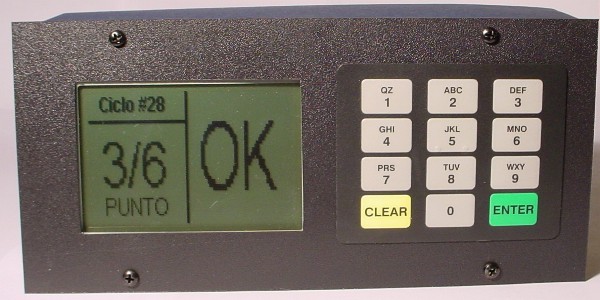

-Decide "good" or "bad" welding with pre-programmed criteria.

-In accordance with the ASTM E751-1 standard.

-100 % spot or stud welding tested and very less destructive test.

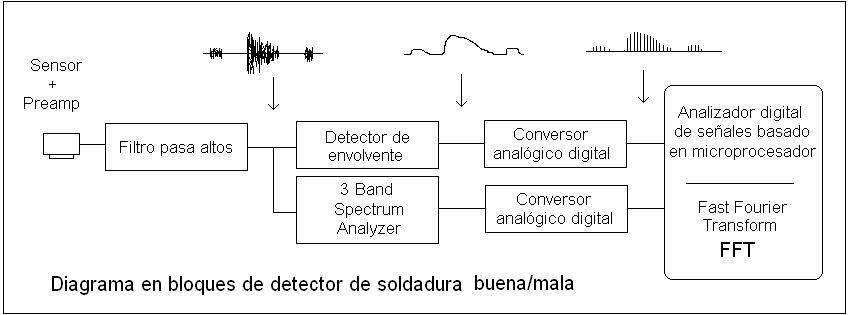

-VN500 is based on Acoustic Emission techniques (see block diagram).

-VN500 detects automatically welding type spot or stud.

-Multiples simultaneous routines of ultrasonic signatures identification.

-Up to 256 different cycles of up to 256 welding each.

-Alerts operator with "Cycle ended" or "Change piece".

-4 digitals TTL digital outputs to control machines, devices or clamps.

-User or Supervisor mode.

-Fully programmable.

-Diary or periodic reports. VN500 can acts like data logger.

-RS232 Serial communication to PC for total logging or statistical analysis.

-Software to transfer data to spread sheets or other application.

-Autonomic for work island.

-Sensors for different materials and configurations.

See

more sensors and preamplifiers

See

more sensors and preamplifiers

-Many types of mechanic, pneumatic and hydraulic clamping devices.

VN500 Block Diagram

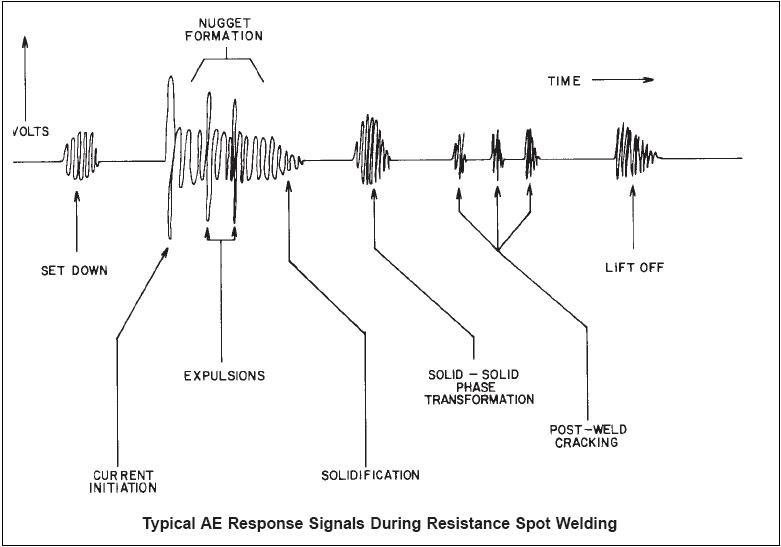

Spot welding signature:

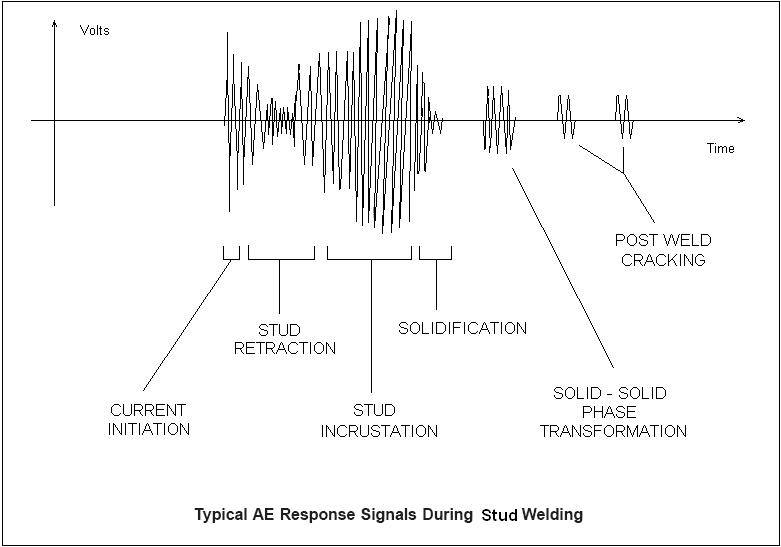

Stud Welding Signature:

contact us info@vn-amps.com.ar

Ing. Carlos María Ortega (UBA)

Riglos 155

1424 Capital Federal

TE 5411 4901 2350